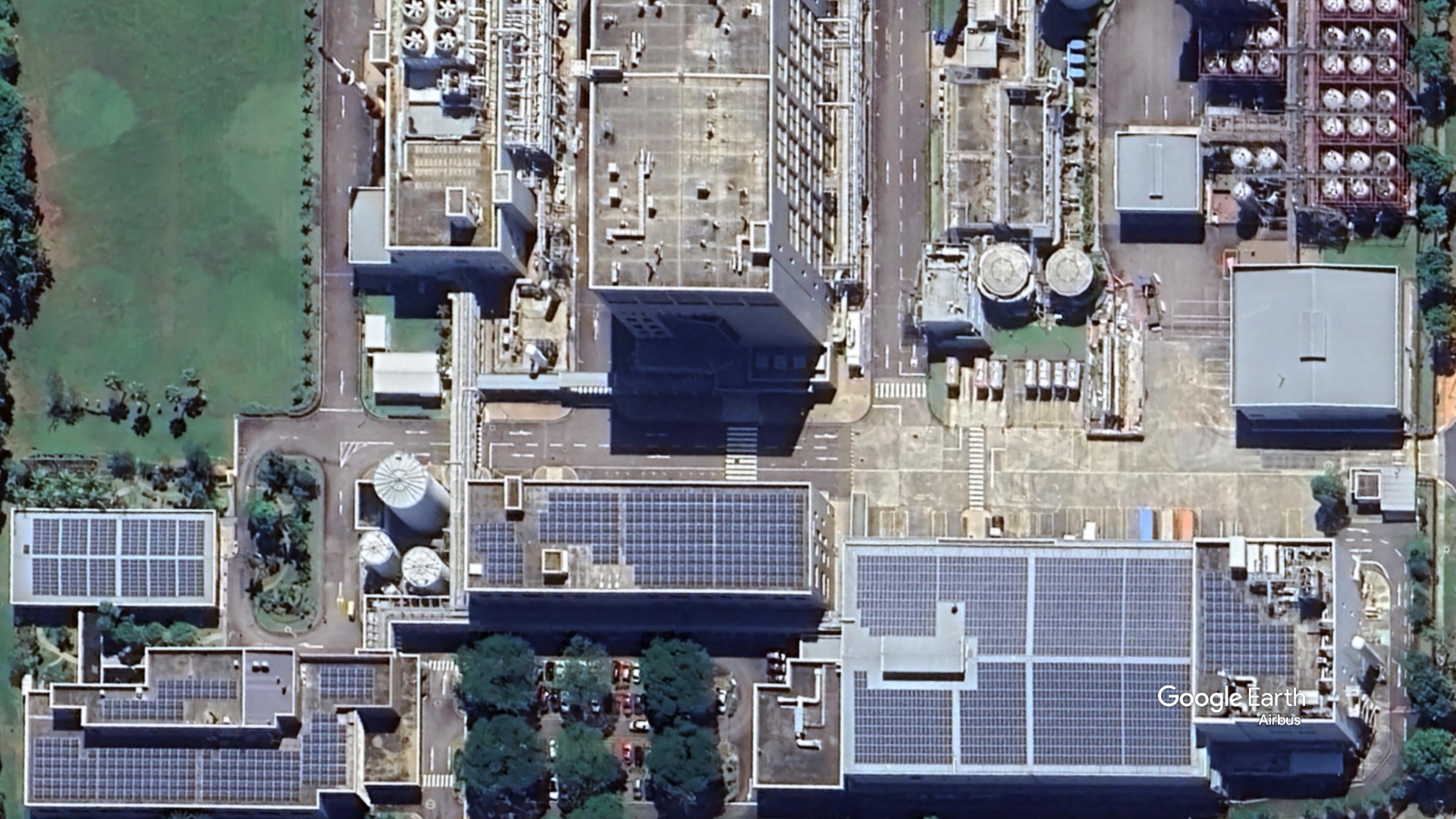

Located within Tuas Biomedical Park, Pfizer’s Active Pharmaceutical Ingredients (API) manufacturing plant began operations in 2003. Spanning approximately 22 acres, the site employs nearly 400 colleagues. Pfizer supports green initiatives by using solar energy to generate electricity for its Tuas manufacturing site and has implemented measures to recycle rainwater and solvents to reduce waste. Additionally, it is the first in the pharmaceutical industry here to recover waste heat for chilled water and steam generation. Pfizer’s new small molecule API plant, Tuas II, has also adopted an additional solar system to further its sustainability efforts.

Pfizer’s roof is a membrane type. Before installation, we measured the tilt of the roof to determine the static coefficient, highlighting the importance of the friction coefficient for ballasted solar systems. Besides the wind’s upward pull, ballasted solar mounting systems are also vulnerable to sliding motion caused by wind forces pulling and pushing against them.

This is because solar mounting systems are designed to rest on the roof without mechanical fixation. Therefore, it is crucial that ballasted solutions are installed with the appropriate amount of weight to prevent them from lifting off or sliding across the roof.

It is important to note that this is not a new requirement or regulation; ballasting against uplift and sliding forces has always been necessary. The required amount of ballast is determined through a series of calculations that analyze and compute all possible forces acting on the solar array, including sliding forces. This is derived from the friction coefficient, which measures the frictional force of a particular material. The friction coefficient varies depending on the material, as some materials have coarser surfaces than others. For instance, the friction coefficient for bitumen is higher than for a membrane. In simple terms, the coarser the surface, the greater the resistance. By determining the worst-case scenario value for the friction coefficient using the static coefficient, we can incorporate this into our calculations. A significant advantage of our solar software ballasted calculations is that we use physically recorded results for both sliding and uplift forces from our extensive wind tunnel testing procedures.

These results not only help us understand how the system will behave but also enable us to determine a more accurate ballast requirement to prevent the solar array from lifting or sliding across the roof.